| Carrying Bracket |  |

|

| Carrying Flat |  |

|

Carrying "Vee" This type of idler is used in less demanding environments where belt speeds are generally less than 2,5 m/s. It is designed for transporting small grain material (gravel, sand). Owing to the shape of the trough it has a lower transportation output than a troughing idler however this is compensated for by its lower cost (amongst other things there is a 1/3 lower need for rollers).

|  |

|

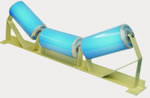

Carrying Troughing Most carrying sets have a troughing shape which allows greater amounts of material to be conveyed. These shape the belt to prevent spillage and are available with 20°, 30°, 35° and 45° trough angles with equal or unequal roller lengths. Troughing carrying sets have 3 rollers supported within the base frame which is fixed to the conveyor structure. Normal spacing is 1 to 1,6 m.

|  |

|

Carrying Garland (suspended) sets Consists of several (3 or 5) rollers, attached together by a chain link. Contrary to troughing sets the maximum angle of the side rollers is 60°. This design leads to greater flexibility of the structure which results in improved belt centring, load containment, higher working speeds and load capacity, better absorption of dynamic stresses during conveying large bulky material, less shut down time and lower installation and maintenance costs.

|  |

|