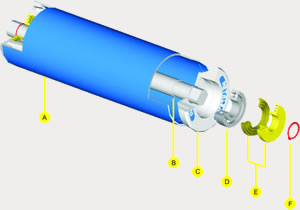

A) Shell

- Manufactured from seamless or lengthwise welded accurate steel tubes of ISO 4200 grade steel

- Wall thickness corresponds to the loading and operating conditions the roller is subjected

to and is optimized by FEM calculations and verified by long-term testing

B) Shaft

- Drawn from ISO 1035 - 1, ISO 1035-4, EN 10278 grade round bars

- The ends of shafts are CNC machined

- The shaft is ground to a fit tolerance of ISO h6

C) Bearing housing

- Silumin-aluminium alloy,pressed steel sheets or casted.

- Bearing fit tolerance to ISO M7

D) Bearing

- Single-row ball bearings are used, with dimensions in compliance with ISO 15

- 2RS - Acrylonitrile butadiene rubber (NBR) seal with sheet steel reinforcement on both sides of the bearing

which prevent contaminants from entering the bearing

- C3 radial bearing clearance provides for optimum roller operation

- Bearings are filled with lithium based water repellent grease

- Bearings are filled to 70 % of the bearing’s free space which provides for operation without

the need for further lubrication throughout it’s service life

E) Labyrinth sealing system

- The system comprises of several sealing elements which prevent contaminants from entering the bearing

- Individual elements of the system are circular in shape with interlard lips which form a labyrinth

- The shape of the lips is designed to prevent the intrusion of contaminants into the bearing chamber

without increasing rotational frictional resistance

- The system has two parts - an inner labyrinth and an outer labyrinth

- The space between the lips of the labyrinth is filled with grease for catching fine dust particles.

- The grease is the same as the bearing grease

- Elements of the labyrinth sealing system are made from silumin-aluminium alloy,pressed steel sheets,plastic or casted.

- The labyrinth system can be fitted with a friction ring to prevent the intrusion of water

F) Circlip

- Manufactured from hardened spring steel in compliance with DIN 471

- Prevents axial movement of the shaft

|